Fuel Tanker for Sale

We are able to provide fuel tankers with a volume of 30000-60000 liters (6600-13200 imperial gallons) in aluminum, carbon steel, stainless steel and other materials. According to different volumes, the gasoline tanker is designed as 2 axles/3 axles/4 axles.

Fuel Tanker Trailer Specifications

We manufacture and sell fuel tankers of different specifications. The following is the specification table of 30000-60000 liters, 2-axle/3-axle/4-axle gasoline tanker:

| 30000-60000 Liters Fuel Tanker Specification | ||

|---|---|---|

| Trailer size (customizable) | 2 Axles | 9400*2200*1750mm |

| 3 Axles | 11650*2500*3950mm | |

| 4 Axles | 13800*2500*3810mm | |

| Medium | Transport fuel, oil, diesel, gasoline, petroleum, crude oil, palm oil | |

| Tank | Material | Carbon steel/aluminum alloy/stainless steel optional |

| Tank thickness | 6mm | |

| Baffle thickness | 6mm | |

| Compartment | 5 or 6 compartments (or customizable) | |

| Manhole cover | Carbon steel or aluminum alloy material | |

| Diameter 500mm, with breathable valve | ||

| Discharge valve | API 3-4 inch discharge valve, can also be used for loading | |

| Bottom valve | Aluminum API pneumatic safety valve emergency valve | |

| Tank testing | 5 psi (35 Kpa) water pressure test for each compartment | |

| Chassis | Axle | 2 axles/3 axles/4 axles |

| L1/BPW/FUWA/other brands | ||

| Landing gear | Linkage or single action | |

| JOST/FUWA/other brands | ||

| Kingpin | 50# or 90# | |

| Bolt or welding type | ||

| Suspension | Mechanical suspension/airbag suspension/steering axle suspension | |

| Brake system | WABCO | |

| Tire | 12R22.5 dual tires/385.65R22.5 super single tire/315.80R22.5 dual tires; brand optional | |

| Accessories | Fire extinguisher, two spare tire straps, toolbox, valve box, dustproof API valve cover, discharge pipe, etc. | |

Gasoline Tanker Design

Based on our track record of successfully designing and producing custom fuel tankers, FUDENG has built a reputation of excellence in the industry. 30 designers and 200 workers have experienced 20 years of in-depth research and experience accumulation, only to design durable and safe fuel tankers.

Use DoublE-sided Welding

The use of double-sided welding can reduce the probability of weld seams, ensuring that no liquid will seep between each compartment during long-term use, and the service life is longer.

Overall Lightweight Design

Through the grasp of the shape, on the premise of ensuring the quality of the fuel tanker trailer, the weight of the whole vehicle is reduced to about 7 tons, and there is no redundant design.

Computer Accurate Calculation

When rolling up the fuel tank, it is calculated by computer and welded at one time with large-scale crimping equipment, so there is no missing welding and no uneven welding.

ISO Compliant Customization

Fuel tankers are customized according to each client’s needs. Including compartments, tank shapes, accessory brands, trailer dimensions, adding custom features and more.

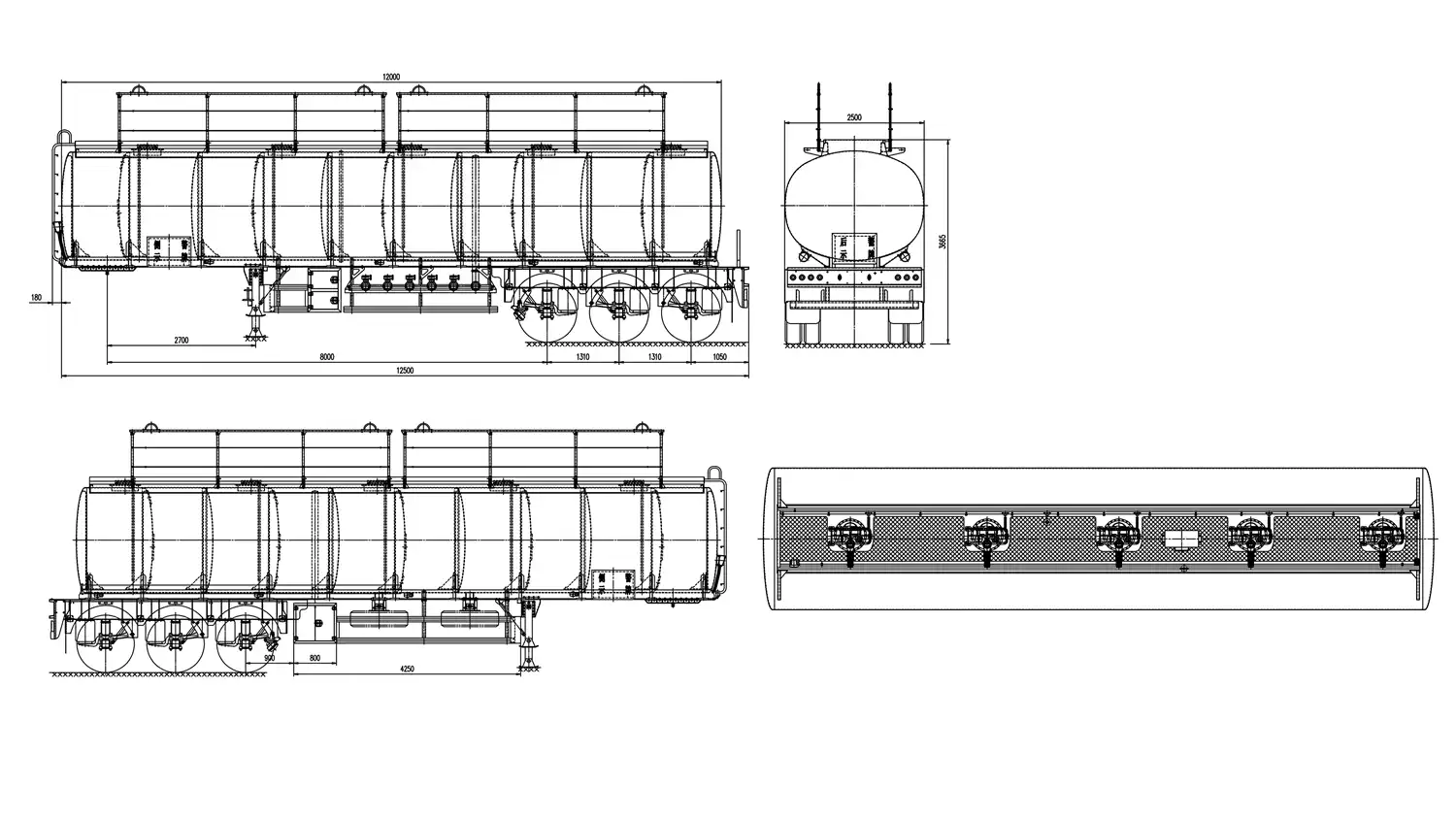

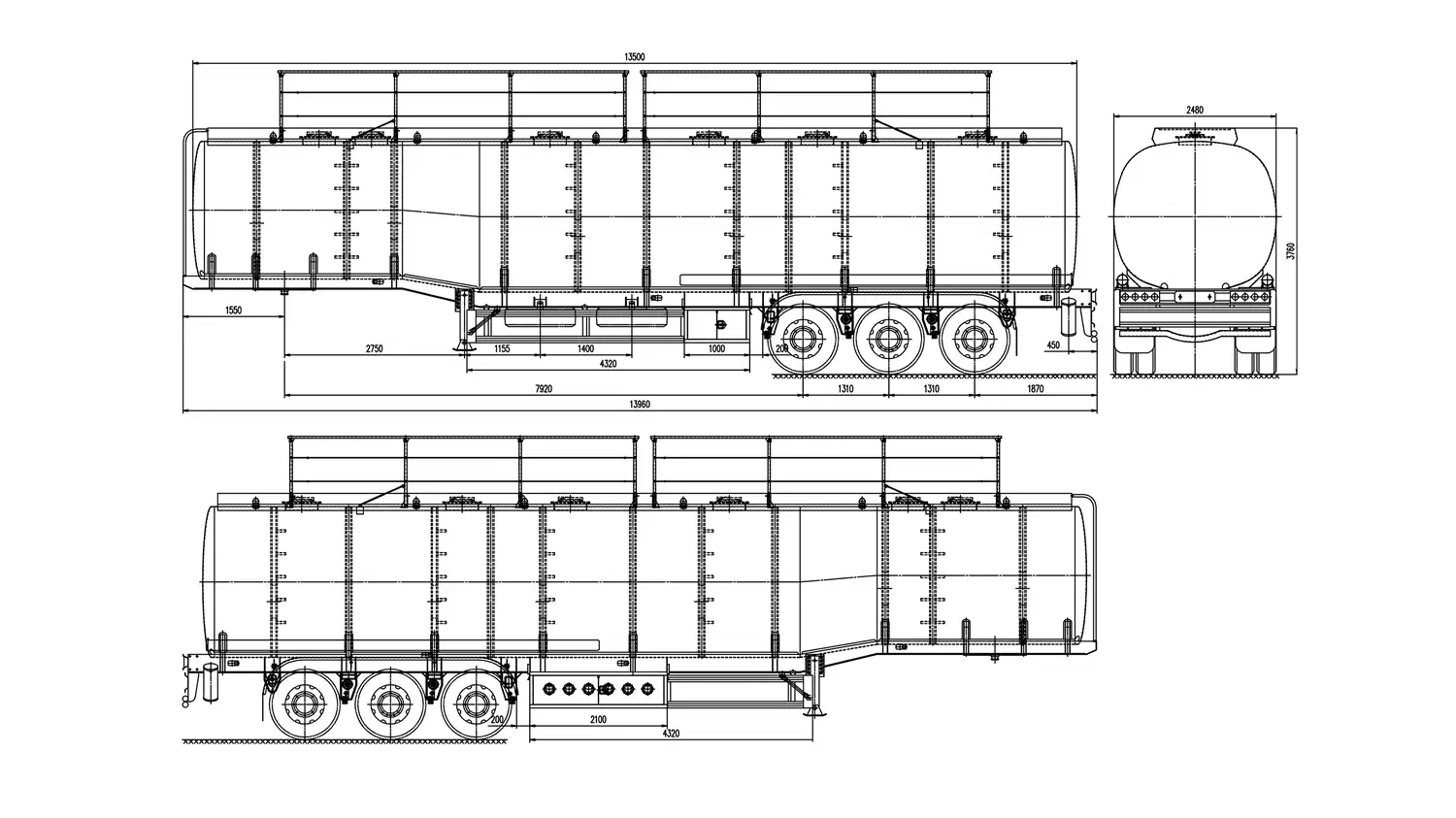

Tanker Trailer Diagram

Before starting to produce fuel tanker, our designers will first design drawings and submit them to customers for confirmation. After confirmation, workers will start production. Please refer to the following 30000l / 45000l / 60000l tanker trailer diagram:

Tanker Trailer Application

Tanker trailers are used in a wide range of applications, from food to industry. The following are liquid cargoes commonly transported by tank trailers:

Petroleum and Petroleum Products Transportation

One of the main functions of the tanker trailer is to transport petroleum and petroleum products. Including gasoline, diesel, kerosene, aviation kerosene, lubricating oil, etc. After these petroleum products are produced from the refinery, they will be transported to various places by tanker trailers. Aluminum tanker trailers are the first choice for transporting this type of cargo due to their corrosion resistance and lightweight. Other than that, using a carbon steel tanker trailer is a good option for cost savings. Because carbon steel is cheaper than aluminum.

Chemical Industry Liquid Transportation

In addition to transporting petroleum products, tank trailers can also be used to transport liquid chemical industrial products such as sulfuric acid, hydrochloric acid, sodium hydroxide, ethanol, and others. These chemical industrial products require transportation between production and distribution. As a specialized vehicle for liquid transport, tank trailers can safely and efficiently transport such goods. However, before using a tank trailer to transport chemical liquids, special treatment is required for the interior of the trailer. Such as coating anti-corrosion coating and so on.

Food Grade Liquid Transportation

Tank trailers are also widely used in the transportation of food-grade liquids. Such as edible oil, drinking water, fruit juice, milk, beverages, etc. After production, these food-grade liquids need to be transported between the production site and the packaging plant on tank trailers. Tank trailers used to transport food need to meet food safety and hygiene standards. These liquids are typically transported on stainless steel tank trailers. Because stainless steel is more in line with food safety and hygiene standards.

Tank Material Comparison

We manufacture fuel tankers in different materials including aluminum, carbon steel, stainless steel. Fuel tankers made from these materials each have advantages and disadvantages. Understanding these can help you better choose tank trailers:

Carbon Steel Fuel Tanker

Advantage:

- Carbon steel is stronger and more durable.

- Steel is cheaper than other materials.

- Carbon steel is easily welded.

- Steel has a high yield strength and is not easily deformed.

Shortcoming:

- Carbon steel is prone to rust, so it must be galvanized or painted on the surface.

- Steel has a higher density and a heavier volumetric weight.

- Not suitable for transporting corrosive liquids.

Aluminum Tank Trailer

Advantage:

- Lighter weight, good fuel economy.

- Aluminum alloy has good corrosion resistance and has a wider range of uses.

Shortcoming:

- Aluminum is more expensive, so it costs more to buy a trailer.

- The strength is low, and it is easily deformed and damaged by external force.

- Aluminum alloy has a low melting point and is not suitable for transporting high-temperature liquids.

Stainless Steel Tanker

Advantage:

- Stainless steel meets hygienic standards and can transport food and medicine.

- Smooth surface, not easy to stain, easy to clean.

- High strength, wear-resistant, durable and anti-oxidation.

Shortcoming:

- The price is higher than that of carbon steel tank trailers.

- Stainless steel is not easy to repair if it is damaged, and the maintenance cost is also high.

- Stainless steel has poor plasticity and it is difficult to manufacture tanks with complex shapes.

Fuel Tanker Factory Visit

As a powerful china trailer manufacturer, FUDENG is always committed to providing customers with the best quality products and services.

We know that the support of our customers is an important force that makes us grow stronger, so we will do our best to meet your needs. FUDENG will provide you with professional product introduction, detailed technical parameters and perfect after-sales service.

We very much welcome you to visit our factory, because this is a great opportunity to show our capabilities to our customers. If you need to make an appointment to visit or consult, please leave your contact information, our staff will contact you as soon as possible. Looking forward to your visit!

Fuel Tanker Production Workshop

FAQ

What are the types of tank trailers?

Common Tank Trailers:

- Aluminum Tank Trailer

- Carbon Steel Tank Trailer

- Stainless Steel Tank Trailer

Special Purpose Tank Trailers:

- LPG Tank Trailer

- CNG Tank Trailer

- Chemical Tanker Trailer

- Asphalt Tank Trailer

What tests do tanker trailers go through before leaving the factory?

- Pressure test: fill the tanker with water or gas and apply pressure to detect whether there is water seepage or air leakage.

- Driving performance test: test the performance of the oil tank trailer in sharp turns, sudden braking, high-speed driving, etc.

- Braking system test: Brake suddenly when driving fast, check whether the braking force and braking distance meet the standards.

- Light test: test whether the front and rear lights, turn signals, brake lights, etc. can work normally.

How much does a tank trailer hold?

The capacity of tank trailers carrying different types of cargo may vary according to the local laws and regulations applicable to the customer.The following are the capacities of different types of tanker trailers:

Chemical Tank Trailer:

Small tanks: 3,800 – 5,000 gallons (14,384 – 18,927 liters)

Standard tank: 6,000 – 7,000 gallons (22,712 – 26,498 liters)

Large tank: 8,000 gallons (30,283 liters)

To prevent product contamination, the interior of the chemical tank trailer has no baffles.

Petroleum Fuel Tank Trailer:

Capacity: 9,000 – 16,800 gallons (34,068 – 63,662 liters)

Able to transport multiple fuels at the same time.

There can be multiple compartments inside to prevent mixing of different fuels.

Sanitary or Food Grade Tank Trailers:

Capacity: 6,000 – 15,800 gallons (22,712 – 59,811 liters)

Weld seam surfaces are polished to ensure no product remains in the crevices.

What preparations should be made before transporting dangerous goods?

Strict regulations and safe practices need to be followed when transporting dangerous goods using tank trailers. Especially liquid chemicals and flammable and explosive fuels. The following are the preparations before transporting dangerous goods:

- Drivers and tank trailers need to obtain corresponding qualifications and licenses. The driver needs to hold a qualification certificate for road transport of dangerous goods. Tank trailers need to obtain the appropriate transport permits. Dangerous goods cannot be transported in the name of individuals.

- Check before departure. Make sure the trailer tank and associated fixtures are in good condition. Check whether safety facilities such as fire and explosion-proof equipment, leak detection devices, and pressure relief valves are working properly.

- The name, hazard nature, hazard signs, warning signs, etc. of dangerous liquid chemicals should be clearly marked on the tank trailer. To identify and respond to emergencies.

- Equipped with corresponding emergency response equipment and measures. Such as leakage emergency treatment equipment, fire extinguishers, first aid equipment, etc. Drivers and staff must be trained in emergency response.

- Carry corresponding transport documents and records. Including the license for transporting dangerous goods, transportation contract, list of dangerous goods, emergency contact numbers, etc.

How are fuel tankers produced?

Step 1: Prepare raw materials

Cut the aluminum plate or steel plate into the standard size and thickness specified by ISO with a plasma cutting machine.

Step 2: Rolling Tank Truck Body

Use a rolling machine to connect multiple aluminum alloy plates or steel plates, and weld and fix them on both sides to form a 6 – 8mm thick metal cylinder.

Step 3: Prepare the front shell and tail shell

Use a plasma cutting machine to cut the front shell into the shape required by the drawing, then use a hydraulic bulging machine to shape it and form it at one time. Finally, use the deep side of the screw machine to make the edge of the head to about 6cm.

Step 4: Make the wave board

Use a plasma cutter and edger to make the desired shape of the anti-wave board according to the drawing. Cut inspection holes of different sizes on the surface of the anti-wave board and arrange them in a staggered manner.

Step 5: Oil storage tank body welding

Fix the tank body of the oil tanker by rotating machinery and adjust it to the appropriate angle. Use automatic welding and double-sided welding, with electrical control and remote monitoring, to avoid missing welding.

Step 6: Install toolboxes, guardrails, etc.

Install toolboxes, guardrails, and other accessories to complete the assembly of the oil tank trailer, forming a complete vehicle.